Micro Engineering Turnout Frog Wire

Jim Exler, Nampa, ID June 5, 2019

Connecting a wire to the ME cast frog can be a challenge. This is my idea and it seems to work.

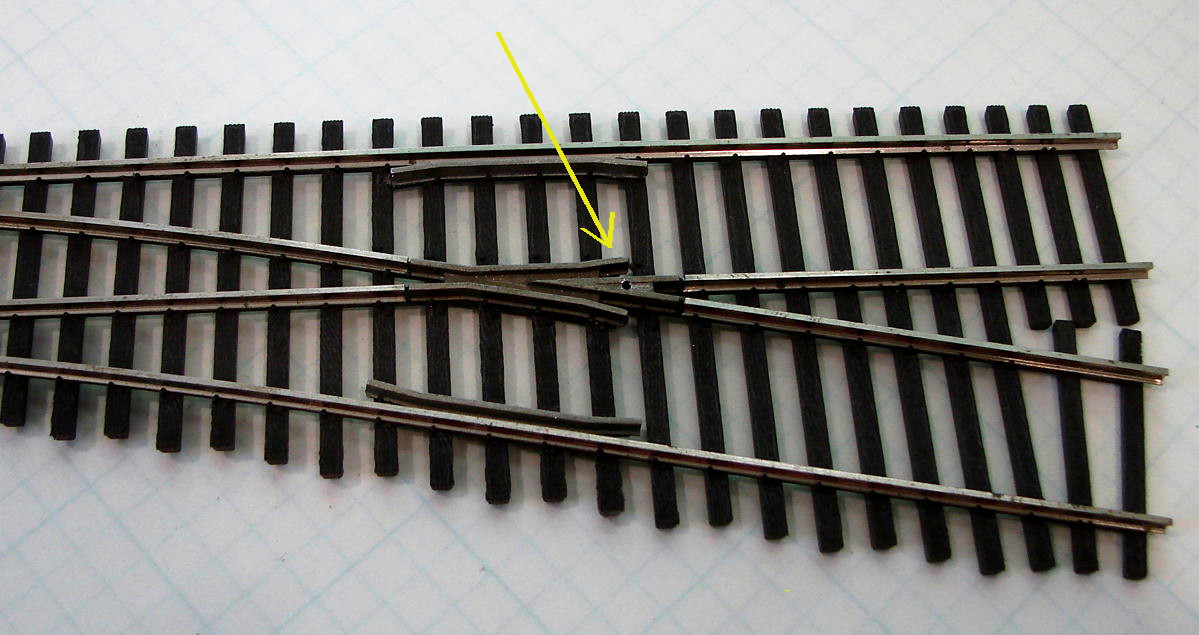

1. First I drilled a 0.9 mm hole down through the frog at its narrowest point. I want easy access and the least amount of metal in the frog that I have to heat for the solder joint.

I decided on 20 gauge (0.032") solid wire (green of course) for the frog. The 0.9 mm (#64) bit I had was hardened to drill circuit boards. With a speed control on my Dremel it worked fine.

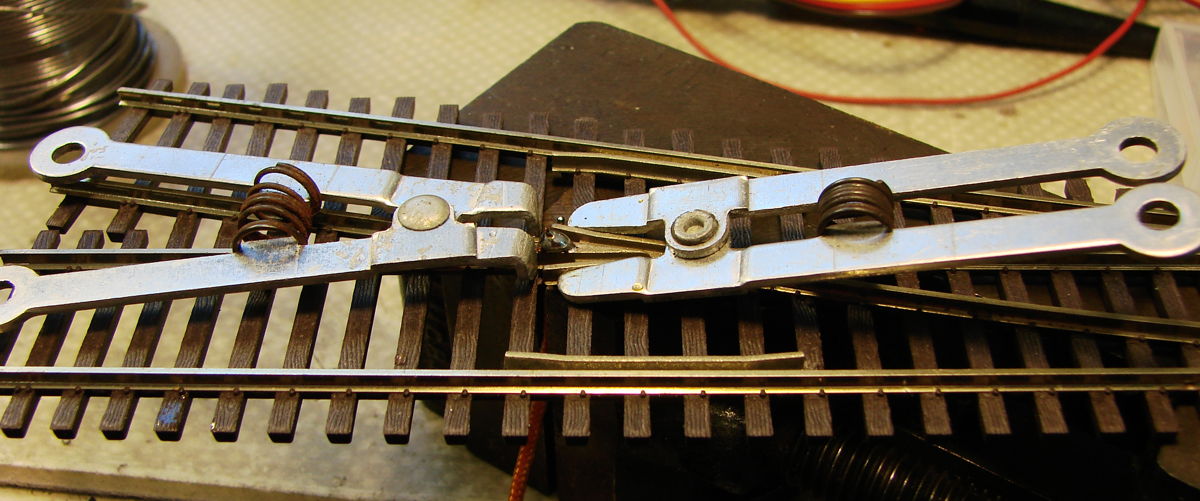

2. Next I stripped about 0.250" of insulation from the wire and inserted it in the hole from the bottom. I also used a couple of heat sinks I had to protect the tie strip from the heat.

After adding a drop of liquid solder flux to the end of the wire which also went into the hole, I used rosin core solder and with a 45 watt soldering iron, I heated the joint as quickly as possible to avoid melting the tie strip. The solder seemed to flow with a good "wetting".

3. I used my rail nippers to remove the bulk of the excess solder and finished up with a knife and a file. As you can see, there is no apparent heat damage to the tie strip or the spike heads.

This is probably best done before the turnout is mounted but I think it can also be retrofitted to an installed turnout.

To insure the integrity of the solder joint, I did a pull test on the wire straight down from the frog. I supported the frog with my finger and pulled 3.5 pounds on a scale with no apparent movement.

Another thought would be to grind a groove from the hole toward the gap that would allow the end of the wire to be bent over and laid flush before soldering.

Click here for ME Frog Wire in Word format